COMPOSITION

Mix of various ingredients including pure cellulose fiber, quartz flour, bentonite, Fossil filtration adjuvant. The paste does not contain watersoluble

materials or chemical products that could damage the treatment materials.

PASTE PREPARATION

Pre-mix the compound with deionized water around 8 hours before in the following proportions:

• 1 part (weight) of powdered mix

• 1.2 parts (weight) deionized water

Mix until the product is completely hydrated. At the end of the process, seal the container with the cover and leave to hydrate for 8 hours. Before

application add a further 1/2 part (weight) of deionized water. The application time is typically 48/72 hours, but can vary depending on the type

of substrate and the level of contamination of the material.

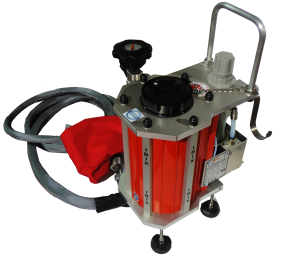

APPLICATION OF THE PASTE

The treatment surface must be mechanically cleaned beforehand with a brush so as to remove the surface deposits of crystal salts and preconsolidated

depending on the state of conservation of the material. The paste is applied manually or by spraying on the treatment surface to

a thickness of around 2cm. The application time can be determined via preliminary in situ tests, so as to optimize the cleaning process. The

paste is removed manually, taking care not to damage the treated surface. Pulp residue can be removed with a damp and non-abrasive sponge.

NOTE:

carry out diagnostic tests to ensure that the surfaces do not have water-repellent layers that impede or limit the action of the extractor (e.g. wax

residue, polymer-based protective substances, film-forming paint or similar materials).