To date, in order to obtain these operating methods it was necessary to mix the two materials externally with a clear waste of time and with the impossibility of returning to work with a single material before having emptied the machine tank.

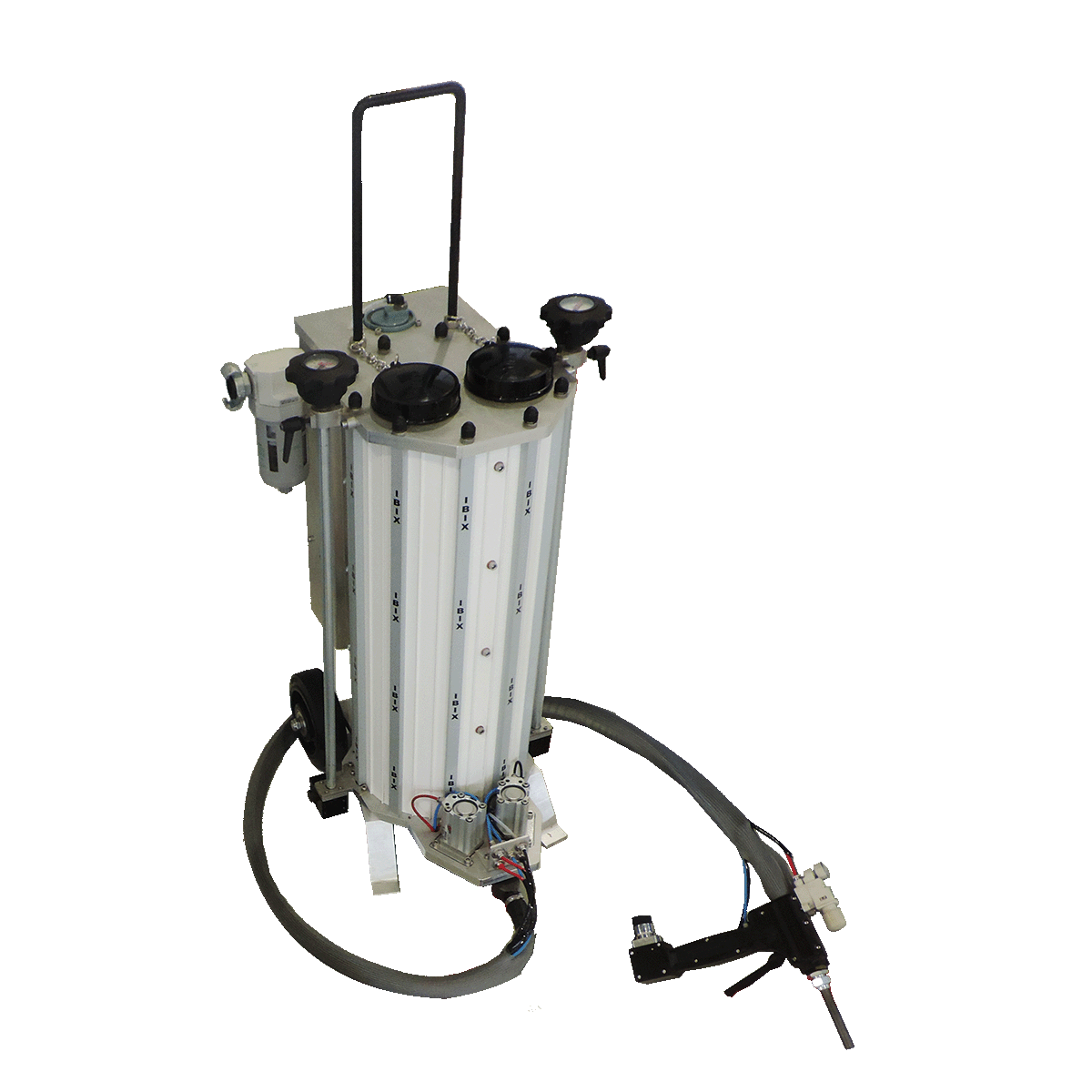

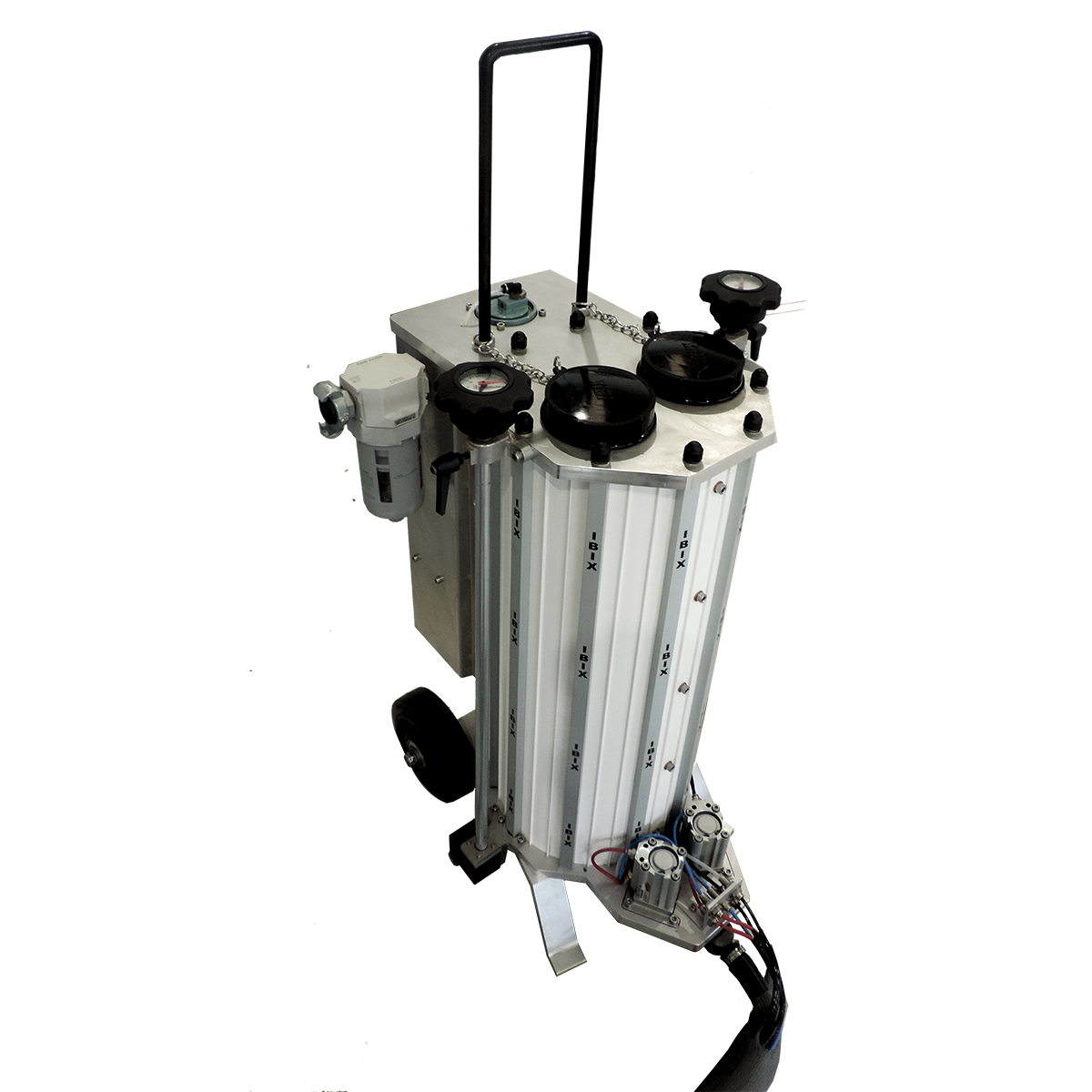

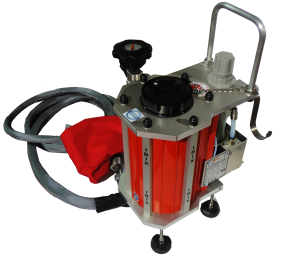

Thanks to IBIX TWIN this problem is brilliantly solved in the Apollo 1 blasting system. The new technology allows the aggregates to be mixed directly from the machine, obtaining uniform and effective surface cleaning.

The TWIN technology of The Apollo 1 revolutionizes the aero-abrasive cleaning with the possibility of mixing two different aggregates in a single operating process.

Philosophy

TWIN is “the most versatile aero-abrasive technology in the world”, an innovative tool created to obtain unsurpassed sandblasting solutions.

Mission

Ibix, through Twin, wants to show how adding two different types of aggregates can revolutionize the way of working: improvement is always possible.

The Apollo 1 Technology

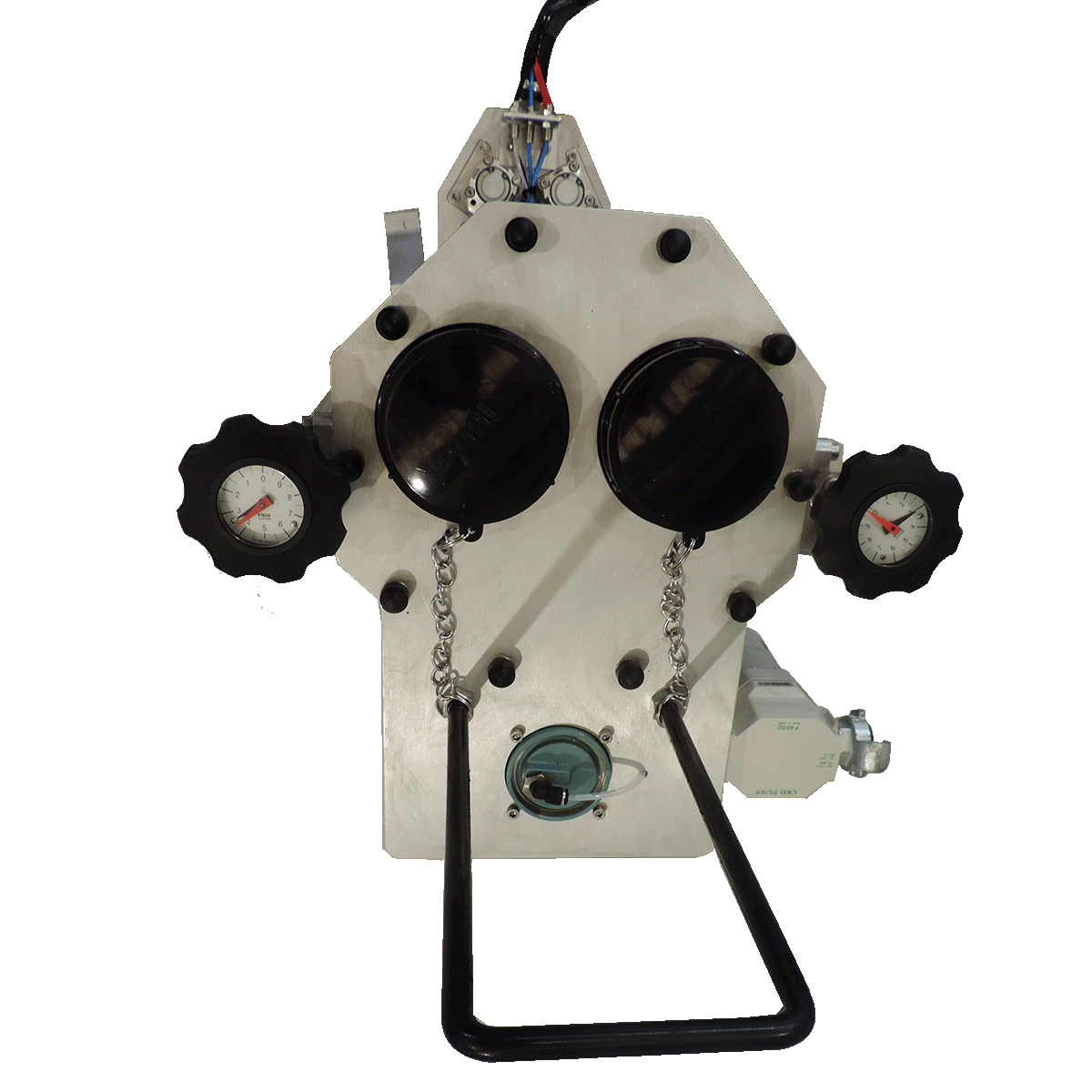

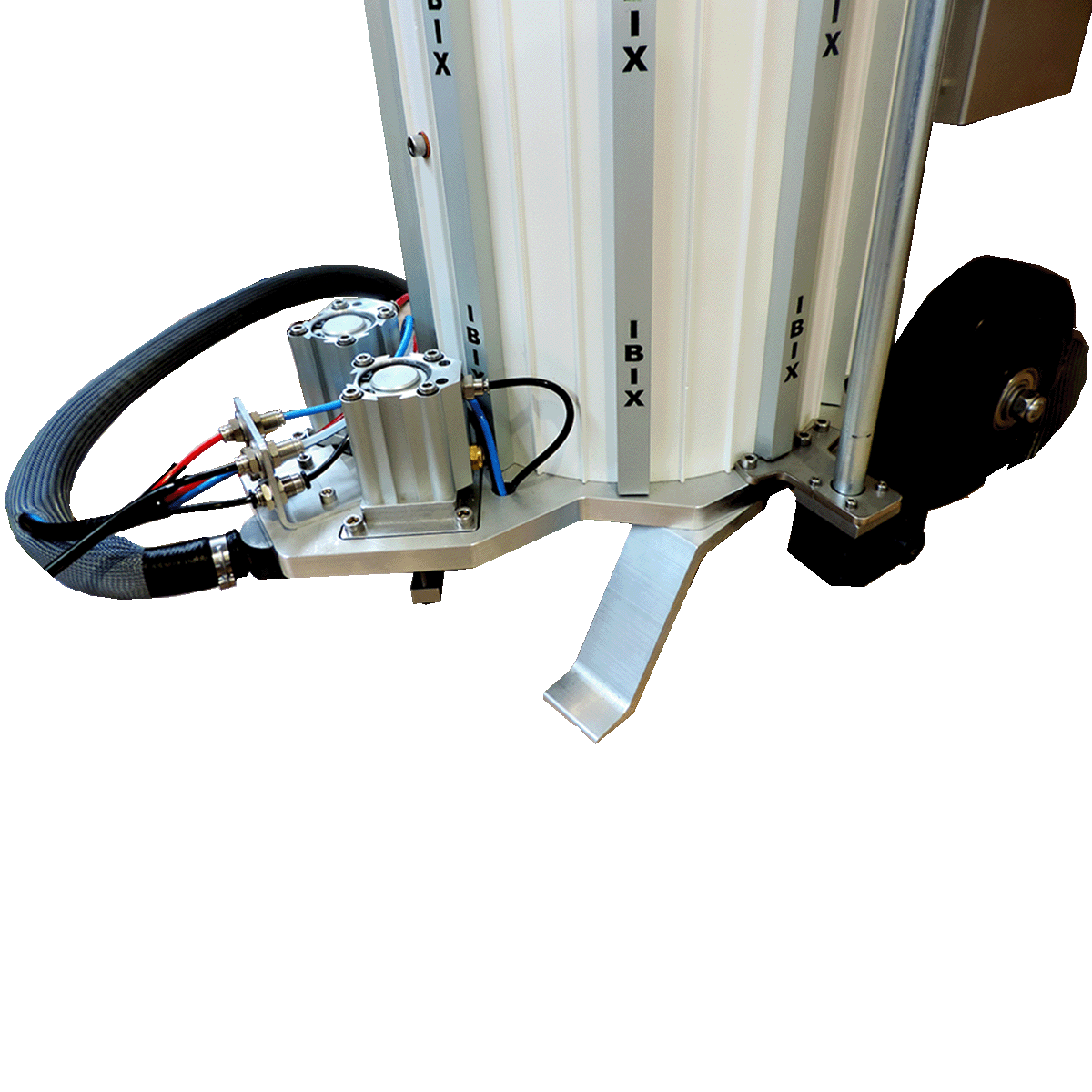

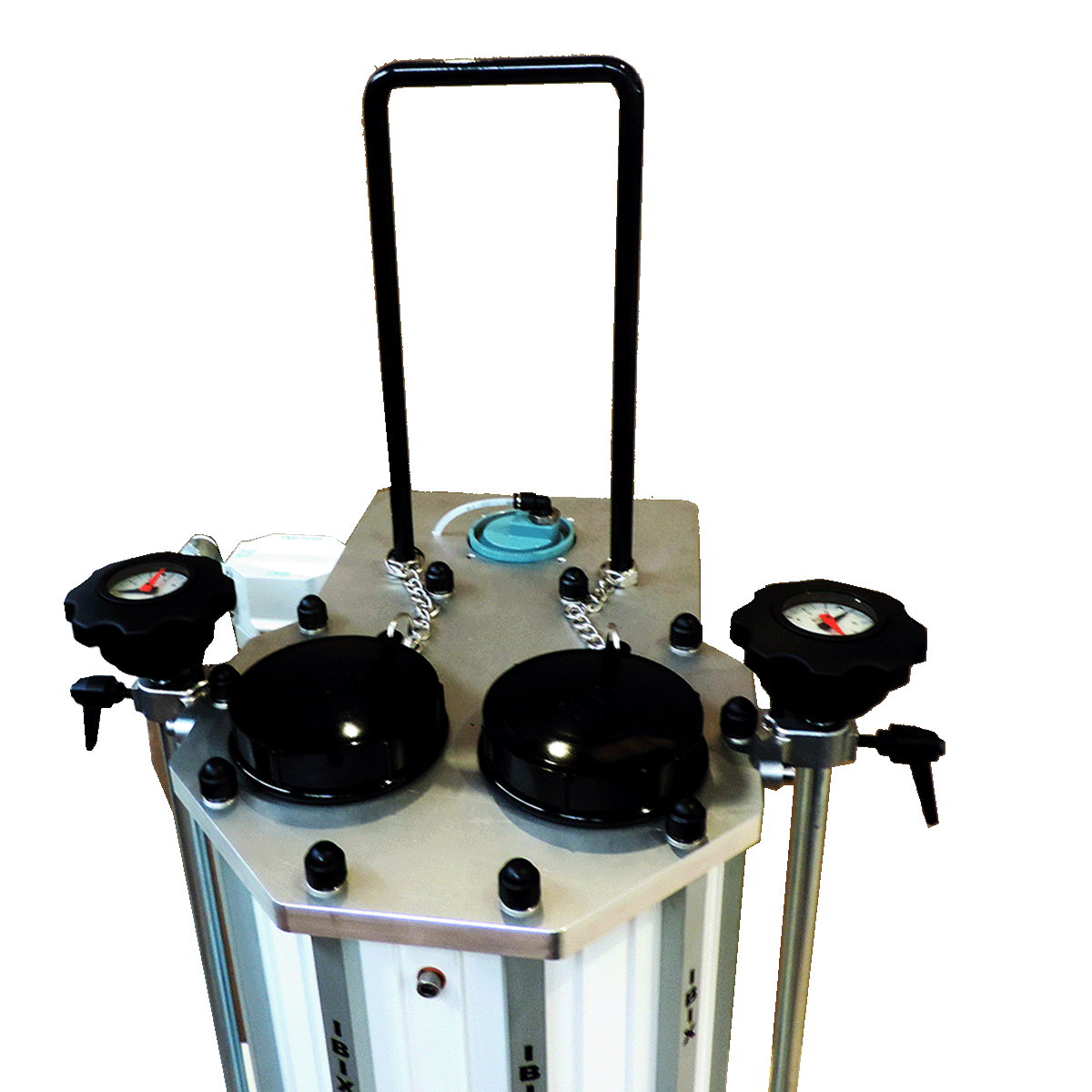

The real innovation of Twin consists in the “double tank” and in the new gun that, combined with the other mechanical parts of operation, create unprecedented values and enrichments.

Application

The treatment of rusty surfaces is more effective if a mixture of a finer and a coarser abrasive material is used. Their combined action effectively removes the rust layer, also acting on the rust deposited at the level of the surface irregularities, such as craters or the like, which is generally difficult to remove.

Operation

- Single aggregate

- Mixed aggregates

- Dry

- Wet

- Sampling

- Micro-blasting

Advantages

- The technological innovation of the double tank, which divides the aggregate tank into two independent halves.

- Higher quality and better result thanks to the possibility of mixing two different types of aggregates.

- Higher productivity. Thanks to a full flow, carrying a major flux of abrasive grains with the same air flow rate.

- Possibility to mix aggregates of different nature.

- The Apollo 1 Blasting System is easy to use!

- Pressure adjustment and tanks activation controls are positioned directly on the gun!

Apollo 1 Blasting System Features

- Pressure adjustment and reading

- Selection of operating tank

- Double filling tank

- Y mixer technology

- 2 aggregate/air mixing valves

- Scientific aggregate regulator, positioned on the top plate, with an indicator showing the quantity of aggregate being released

- Double hopper

- H2O gun with tank selector and pressure adjustment

Download the Apollo 1 System Specifications in the Product Manuals and Downloads Section Below

Equipment

- The pressure regulator is readable even when the machine is in stand-by mode.

- Hose extension: 3/5 meters

- Big pressure gauge for air pressure reading

Maintenance

Proper maintenance of your IBIX Equipment is crucial to optimum performance. Download our maintenance checklist to help keep your IBIX Blasting Equipment in top condition.

Download the Apollo 1 Maintenance Checklist in the Product Manuals and Downloads Section Below

Contact IBIX USA

To learn more about the Apollo 1 Blasting System or any of our other amazing blasting equipment, call us at (727) 776-4646 and speak to a technician about scheduling a free demonstration. You can also contact us on our website here. We look forward to serving you.